Why Choose Dry Ice CO2 Blasting?

Dry ice blasting is beneficial in many scenarios in the restoration industry. It is a nondestructive method of cleaning all types of surfaces in a delicate manner using CO2. Dry ice sublimates back to vapour form and is optimal for interior environments as clean-up is minimal.

Dry ice blasting is very clean and is optimal for interior environments as clean-up is minimal. There are many applications for dry ice blasting - CO2 it is CFIA approved and meets the cleanest of standards for all projects.

5 Reasons to Use Dry Ice Cleaning

- Increases uptime through in-place cleaning

- Cleans without damaging the substrate

- Reduces/eliminates the need for hazardous solvents

- Quicker and more thorough than cleaning by hand

- Safe around electrical components

Dry ice cleaning method has not only revolutionize the cleaning process of the pulp mill industry but in all industries. It has made most of the equipment to operate at peak efficiency with minimal downtime.

Dry Ice Blast Cleaning is Efficient and Eco-Friendly

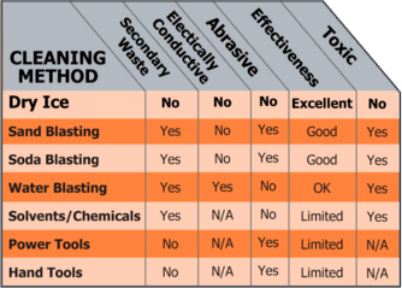

The Dry Ice Blasting process is superior to blasting with sand, glass beads, and other types of cleaning methods for numerous reasons. As an Eco-friendly cleaning alternative, the dry ice cleaning method is quickly becoming favored for environmental as well as production reasons. Due to the nature of the Dry Ice Blasting process, there is no waste to be disposed of. Tremendous performance gains of little to no production downtime, quality of the clean, no clean-up, and minimized damage to equipment make Dry Ice Blasting a cost-effective cleaning option.

F E A T U R E S

Why Use Dry Ice?

01

Decreases downtime of the equipment.

Dry ice blasting method does not need the equipment to be disassembled when cleaning. The time consumption in disassembling the equipment is eliminated. The ability to clean the equipment in place without disassembling also eliminates:

-The process of transporting the equipment to the cleaning area.

-Reassembling time

-Cooling down time

-Reheating time

The dry ice cleaning method reduces the downtime period from days to hours.

02

Faster and more thorough cleaning.

Superior cleaning is achieved and at the same time reducing the cleaning hours compared to other scrubbing methods. It also cleans areas that can not be reached by hand.

03

Reduction of waste disposal.

Other methods of cleaning lead to secondary contaminants which are the cleaning agents used in the process. This does not apply in the case of dry ice cleaning/blasting method since the CO2 evaporates upon contact.

04

Increased safety.

The CO2 is nonhazardous and nontoxic giving an advantage to employees, environment and for the equipment.

05

Elimination of equipment damage.

Other methods such as sandblasting can lead to the removal of the surface due to aggressive and abrasive effects whereas the dry ice cleaning/blasting method takes care of the surface by lifting the contaminant away. The cleaning without disassembling also eliminates the possibility of damage to the equipment during relocation from and to the cleaning dedicated cleaning area.

06

Lower cost.

The cost incurred in dry ice cleaning/blasting method is considerably lower compared to other methods which use cleaning agents and are more labor intensive

SPECIALIZATION

Industrial Cleaning

Are you tired of the costly downtime and excessive waste that results from the cleaning and maintenance of your industrial facility?

Traditional cleaning methods for facilities and warehouses take time, and can require the disposal of a large amount of secondary waste. With dry ice blasting, you can get the job done 3-5 times faster and eliminate all secondary waste!

By using dry ice pellets that are propelled at supersonic speeds onto any surface that requires cleaning, dry ice blasting is an efficient and effective alternative to media blasting, pressure washing and chemical cleaning. Dry ice is non-conductive, non-flammable and generates no additional waste. Long story short; no mess, less clean-up, and lower disposal costs! Unlike pressure washing or steam cleaning, dry ice blasting allows you to put your equipment back online immediately as it requires zero dry time!

For equipment that is sensitive to moisture and can be easily damaged by a traditional industrial cleaning company that uses methods such as pressure washing, dry ice blasting offers a safer alternative. Dry ice pellets transform directly from a solid to a gas, with no liquid phase and with no leftover residue. This makes it the perfect option for industrial equipment that is sensitive to moisture. Additionally, it is non abrasive, nonconductive and nonflammable!

How Other Cleaning Methods Can Be Toxic:

Secondary Waste to be cleaned up in addition to the toxic substrate

This is created by methods such as Sand Blasting, Soda Blasting, and even Water Blasting can leave toxic secondary waste to be cleaned up in addition to the toxic substrate

Kills Surrounding Vegetation

Soda Blasting, Chemical & Solvent Cleaning Methods

Creates Toxic Waste to be Disposed of

Chemical and solvent cleaning methods

Harmful Work Environment Created

Workers are exposed to potentially harmful substances airborne and secondary waste through the use of chemicals and solvents